Search

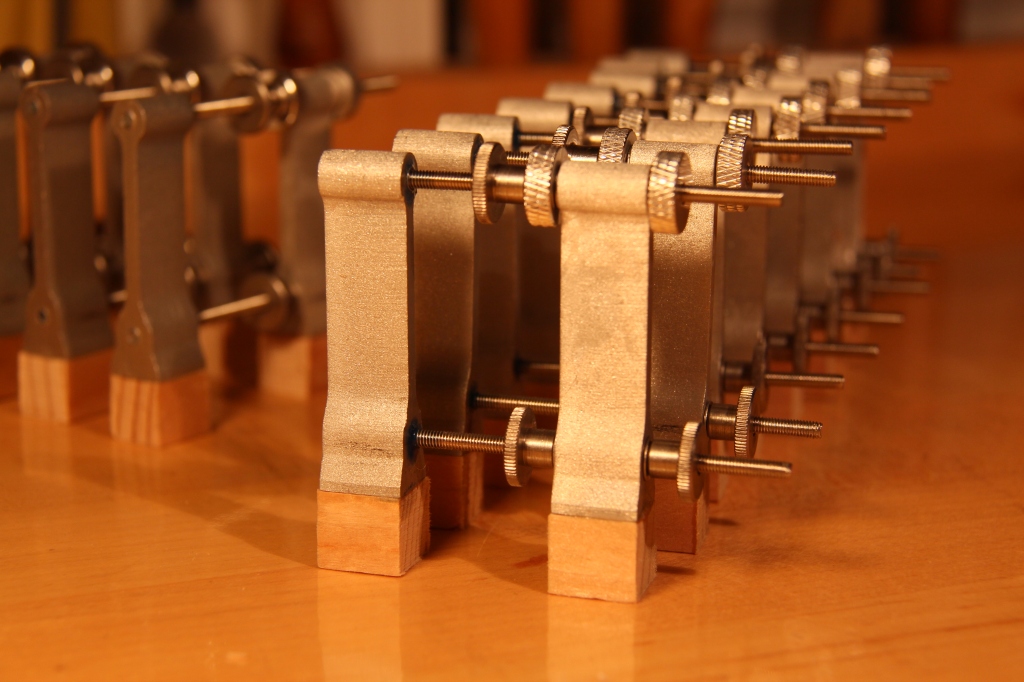

Aluminum Tower Block Clamps

Code

546224

€58.93

In stock

Aluminum tower clamps made by Christian Schabbon are used for cracks repair. They are mounted and glued to the inside of the plate to level and glue the crack. They also have a wide variety of applications.

- Buy 4 for €55.98 each and save 5%

- Buy 6 for €53.04 each and save 10%

- Buy 8 for €50.09 each and save 15%

- Buy 10 for €47.14 each and save 20%

Details

Aluminum tower block clamps

The new crack clamp.

- Cleaning.

- Repairing.

- Glueing.

- And more

Cleaning

- Aluminum tower blocks facilitate cleaning cracks in a much easier and safer way. The sides of the cracks cannot accidentally chafe against each other. Open and close in a very controlled manner.

Repairing

- Aluminum tower blocks simplify fitting slivers in gaps in the crack where (replacing missing wood). Both sides register in exactly the same position every time after closing, a challenge especially if the crack is very long or the plate is completely separated into two pieces.

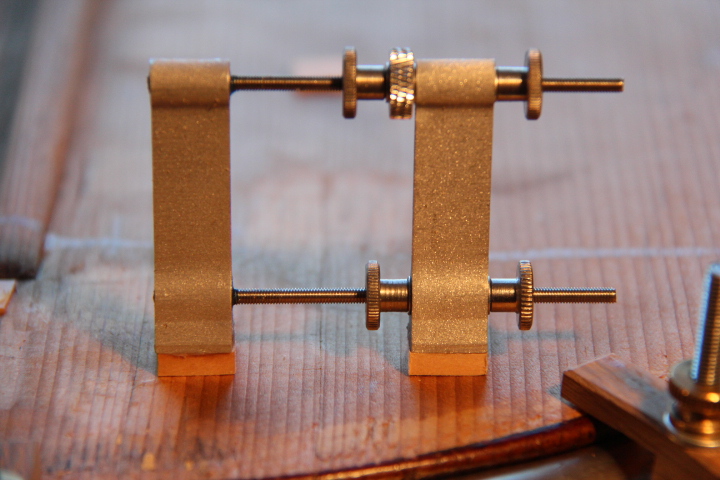

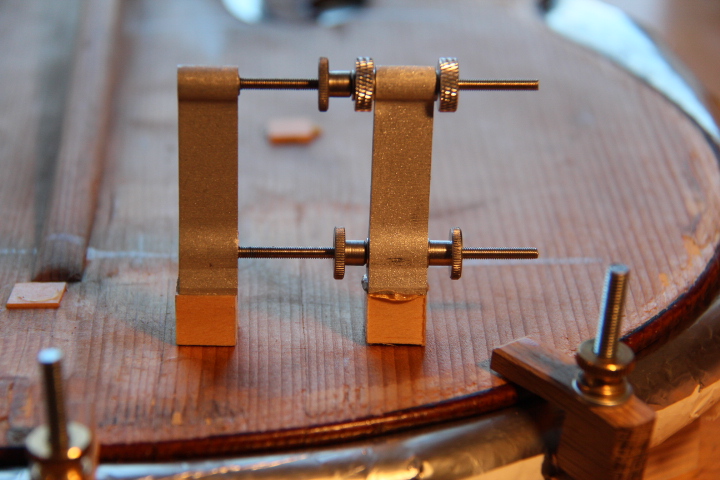

Glueing

- Tower blocks glued to the underedge. Please notice the wedge used to level the crack when free-gluing.

- Towers facilitate inserting glue. Repeatedly opening and closing just one screw pumps glue in the crack. Tightening the clamp then immediately applies the final closing force.

Rib cracks

- Gluing rib cracks in conjunction with a plaster backing.

Multiple cracks

- The towers can span over multiple cracks.

Plaster cast gluing

- The clamps can be used in conjunction with a plaster cast. Their wide span allows for space to place repair clamps that press the plate into the cast.

- Important note: When working with spruce, it is advisable to keep the downward force for a maximum of 10 minutes after glue application to avoid compression and sinking, removing the repair clamps while leaving the tower clamps in place.

Tower clamps – explained

Aluminum tower clamps are used for crack repair. They are fitted and glued to the inside of the plate. They have a wide variety of applications:

- The clamps will safely hold a crack open while cleaning.

- Glue can be pumped into the crack by repeatedly opening and closing the crack with the knurled nut.

- Pieces can be fitted much more easily, the clamps guarantee controlled opening and closing, the sides of the crack will register in the same place each time.

- After glue application the crack can be closed in seconds.

- The plate can be clamped into a plaster cast and vertical force can be applied to level the crack.

Which type of clamp suits which application?

Aluminum tower clamps are best if:

- A plaster cast present.

- Significant crack cleaning is involved.

- Glueing in the plaster cast or with backing.

- Plate is separated into two pieces.

- Missing pieces have to be inserted.

Wooden blocks in conjunction with g-clamps are best if:

- Minimal cleaning of the crack is necessary.

- Glueing without cast or backing.

Installing tower clamps

- Chalk fitting the clamps while the plate is clamped into the plaster cast.

- Titebond original is ideal to glue the clamps to the inside of the instrument.

Correct installation:

- Tower clamps should be installed as close to the plate as possible to prevent shearing.

- Please install a temporary safety cleat to prevent the crack from opening further.

Incorrect installation:

- Tower clamps can sheer of their wooden blocks especially if the later are left too high.

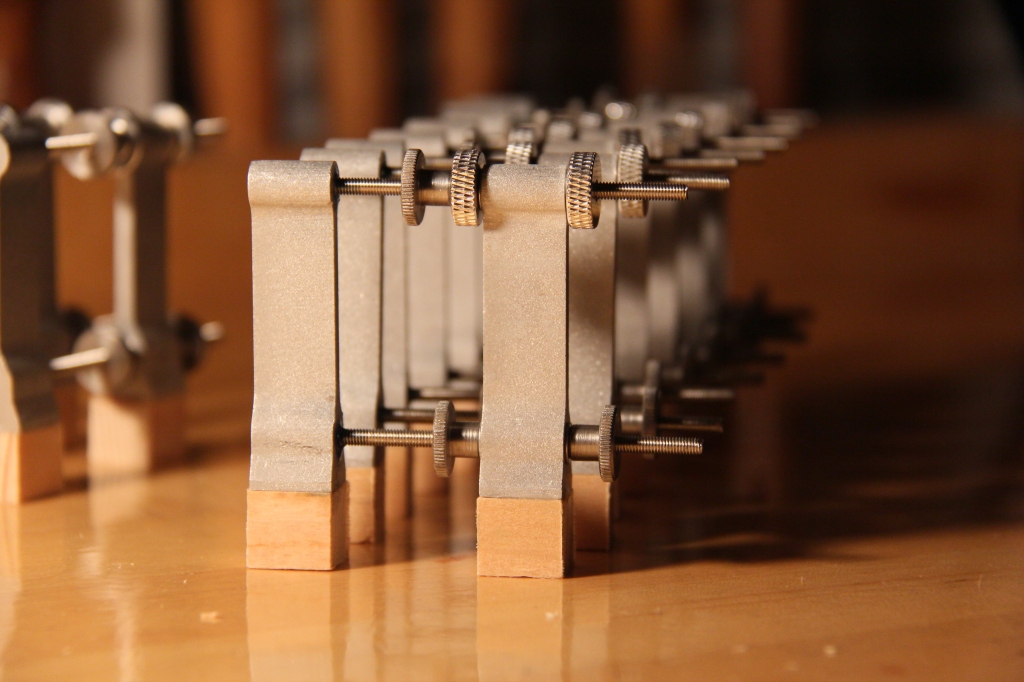

Spacing

- Spacing the clamps too far apart may cause insufficient closing force.

- 30mm spacing between the clamps is recommended.

Torque

- The thread on the rods is very fine. Hence very little torque will exert strong force when closing the clamps. Excessive force can cause the blocks to shear of. Please use the tips of your finger with minimal effort when tightening the clamps.

- Using low blocks will significantly reduce the risk of shearing

Glueing wooden blocks to aluminum clamps:

- Cyanoacrylate 2P-10 gel super glue creates a strong bond. No clamping is necessary. A small bead of excess super glue should be left in place, it will increase bond strength.

- Please avoid Epoxy or Polyester resin, the bond will not be strong enough.

Removing tower clamps

- Tower clamps are easy to remove and ready for next use in minutes. Plane and add material to the wooden block.

Reuse

- The clamps can be reused infinitely.

- A disc sander can be used to prepare the tower clamps for reuse.

- Preparing the clamps for next use with a plane.

- Most of the time it is sufficient to cut the old blocks back and add more material.